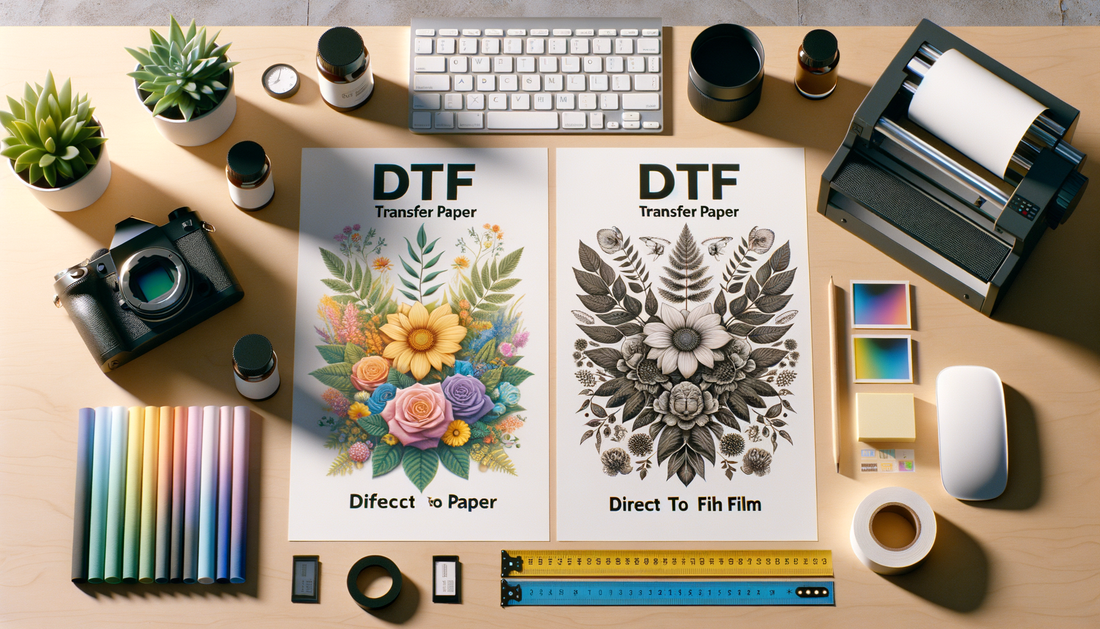

DTF Transfer Paper vs. DTF Film: Which is Right for Your Next Project?

Share

You've got your next big custom apparel project lined up, but the question remains — which material should you use? In this era of digital technology, Direct To Film (DTF) transfers and films have manifested as popular choices. Both materials offer unique advantages and considerations. By the end of this blog post, you'll be equipped to make an insightful decision on which kind of material is right for your next venture. We'll discuss the merits of DTF transfer paper and DTF film in detail so that you can identify the best approach to bring your creative visions to life.

Firstly, let's delve into the realm of DTF transfers. DTF transfers offer a high resolution, repairable, and vibrant solution for apparel design. If you're looking for a product that's easy to handle and produces highly detailed images with vibrant colors on your custom t-shirts in Orange County and beyond, DTF transfers might be your go-to.

One of the major advantages of using DTF transfer paper is that they are easy to store. They take less space, and you don't have to worry about them getting scratched or damaged. You can conveniently carry them from one workspace to another - making them an ideal solution for small-scale or entry-level businesses in regions like Los Angeles County, or San Diego County. Not to mention, their usage does not require additional resources, such as application tapes or films.

But what if you're based in Riverside County and looking for a solution that allows a little more flexibility? Fear not, DTF transfers have you covered. DTF transfers provide an opportunity to print on versatile materials. And when it comes to producing custom t-shirts or tote bags, the flexibility and durability of these transfers become an excellent advantage to have. They can efficiently handle washing and ironing, and can offer you the resilience that apparel demands.

Searching the phrase 'DTF printing near me' may cause confusion due to the influx of options. However, it's essential to consider the nature of your project. Are you looking to design apparel like custom t-shirts or tote bags, or are you thinking beyond fabrics? With UV DTF Stickers, you can think beyond the fabric and consider designing on hard surfaces.

The UV DTF method adds an extra layer of protection on top of your prints, which makes them perfect for hard surfaces. If you're looking to diversify your project to include materials such as wood, metal, glass, ceramic, and more, UV DTF for hard surfaces might just be your answer.

Are you a business based in Long Beach or Pasadena looking to make a comprehensive sticker set? Whether it's for branding purposes or for merchandise, UV DTF stickers give you the freedom to create vivid and durable stickers. They can stand up to extreme circumstances such as water, sun, and rough handling because of their UV resistance.

When you decide to go down the DTF film route, it's as simple as the term 'DTF gangsheet upload'. A gangsheet is a sheet that contains multiple designs or images that will be transferred onto different substrates. The process of creating a gangsheet with DTF film is a great way to maximize your design output and reduce costs.

However, every method has its trade-offs. One of the things to consider while using DTF film is that storing them can be slightly more challenging than DTF Transfer Papers. They may require more space, and you need to be cautious about any potential damage such as scratches or wrinkles in the film.

In case you're a business operating from Burbank, Chula Vista, or lets say Oceanside, you might be worried about the cost. Using DTF film can be slightly more expensive than using DTF transfer papers. Why? Because it is commonly used along with other resources such as application tapes or laminates for the best results.

Both DTF transfers and DTF films offer unique benefits. If your business in Orange County prioritizes flexibility and easy handling, then DTF transfers might just be the answer. On the other hand, if your project involves hard surfaces and you're looking for excellent durability, DTF films, particularly UV DTF stickers, might be the right choice.

Lastly, both hard and soft substrates can benefit immensely from DTF technologies offering a range of opportunities for creative ventures. So, it all boils down to what aligns closely with your specific needs. Now that you have a comprehensive understanding, you can confidently decide what's best for your next project. Remember that the purpose of your project should guide your decision. Happy printing!

Firstly, let's delve into the realm of DTF transfers. DTF transfers offer a high resolution, repairable, and vibrant solution for apparel design. If you're looking for a product that's easy to handle and produces highly detailed images with vibrant colors on your custom t-shirts in Orange County and beyond, DTF transfers might be your go-to.

One of the major advantages of using DTF transfer paper is that they are easy to store. They take less space, and you don't have to worry about them getting scratched or damaged. You can conveniently carry them from one workspace to another - making them an ideal solution for small-scale or entry-level businesses in regions like Los Angeles County, or San Diego County. Not to mention, their usage does not require additional resources, such as application tapes or films.

But what if you're based in Riverside County and looking for a solution that allows a little more flexibility? Fear not, DTF transfers have you covered. DTF transfers provide an opportunity to print on versatile materials. And when it comes to producing custom t-shirts or tote bags, the flexibility and durability of these transfers become an excellent advantage to have. They can efficiently handle washing and ironing, and can offer you the resilience that apparel demands.

Searching the phrase 'DTF printing near me' may cause confusion due to the influx of options. However, it's essential to consider the nature of your project. Are you looking to design apparel like custom t-shirts or tote bags, or are you thinking beyond fabrics? With UV DTF Stickers, you can think beyond the fabric and consider designing on hard surfaces.

The UV DTF method adds an extra layer of protection on top of your prints, which makes them perfect for hard surfaces. If you're looking to diversify your project to include materials such as wood, metal, glass, ceramic, and more, UV DTF for hard surfaces might just be your answer.

Are you a business based in Long Beach or Pasadena looking to make a comprehensive sticker set? Whether it's for branding purposes or for merchandise, UV DTF stickers give you the freedom to create vivid and durable stickers. They can stand up to extreme circumstances such as water, sun, and rough handling because of their UV resistance.

When you decide to go down the DTF film route, it's as simple as the term 'DTF gangsheet upload'. A gangsheet is a sheet that contains multiple designs or images that will be transferred onto different substrates. The process of creating a gangsheet with DTF film is a great way to maximize your design output and reduce costs.

However, every method has its trade-offs. One of the things to consider while using DTF film is that storing them can be slightly more challenging than DTF Transfer Papers. They may require more space, and you need to be cautious about any potential damage such as scratches or wrinkles in the film.

In case you're a business operating from Burbank, Chula Vista, or lets say Oceanside, you might be worried about the cost. Using DTF film can be slightly more expensive than using DTF transfer papers. Why? Because it is commonly used along with other resources such as application tapes or laminates for the best results.

Both DTF transfers and DTF films offer unique benefits. If your business in Orange County prioritizes flexibility and easy handling, then DTF transfers might just be the answer. On the other hand, if your project involves hard surfaces and you're looking for excellent durability, DTF films, particularly UV DTF stickers, might be the right choice.

Lastly, both hard and soft substrates can benefit immensely from DTF technologies offering a range of opportunities for creative ventures. So, it all boils down to what aligns closely with your specific needs. Now that you have a comprehensive understanding, you can confidently decide what's best for your next project. Remember that the purpose of your project should guide your decision. Happy printing!